Design and Development

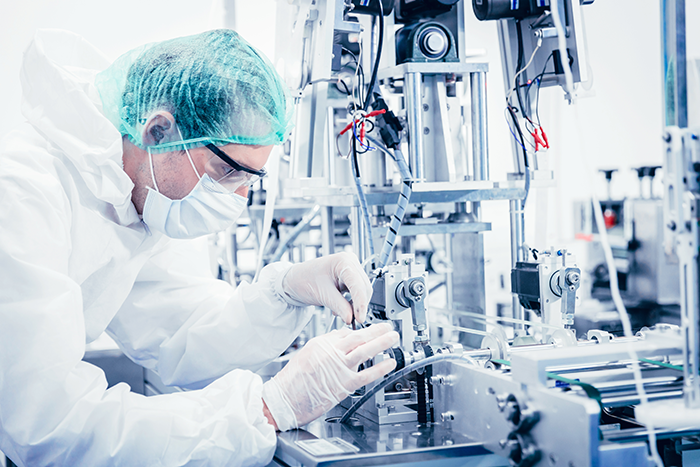

DirectMed specializes in helping our customers design and source high-quality medical components from around the world. As a distributor combining the best of straight-line manufacturing and custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. We can select or design the right part for its intended function.

We work with the best manufacturers around the globe to produce the highest quality components to precise specifications. With almost thirty years in the industry, our objective has always been to provide top-quality products and a first-class customer service experience from design to delivery.

Start a Conversation

Design

Our customer’s journey begins with either the selection of an existing product in our sample range or by choosing to create a new custom design. We provide engineers and buyers with an extensive array of medical components which they can access by either visiting our website or by requesting a printed catalog. We readily send samples upon request. We can modify standard items to fit a customer’s unique requirements for tubing size or type of material. When a stock product does not meet a requirement, our engineers and designers assist with taking an idea from concept to production, providing support through the entire development process right up to obtaining regulatory agency approval.

- Extensive plastic injection molding and overmolding capabilities

- Clean room molding, packaging, & kitting

- Part design & mold design

- Mold qualifications & process qualifications

- Robotic pick & place

- CMM/Vision System Inspection

- ISO13485 certified operations

- Strong financial stability and sustainability

- Quality documentation to fulfill regulatory requirements

Production

We fulfill production requirements by collaborating with our manufacturing partners in the medical industry. Our partners have extensive experience in plastic injection molding and are up to date in the utilization of the latest technology. Qualified DirectMed manufacturing partners are located throughout the US, the EU, Mexico and Taiwan. All our partners provide:

- Extensive plastic injection molding and overmolding capabilities

- Clean room molding, packaging, & kitting

- Part design & mold design

- Mold qualifications & process qualifications

- Robotic pick & place

- CMM/Vision System Inspection

- ISO13485 certified operations

- Strong financial stability and sustainability

- Quality documentation to fulfill regulatory requirements

Fulfillment

The process concludes with the DirectMed team designing a fulfillment process that meets the needs of our customer’s supply chain. DirectMed has close to 30 years of experience with international and domestic shipping and logistics. We are experts in systemizing the on-time delivery of our customer’s orders. Additionally, we have adequate inventory capabilities that can easily support a Kanban or Just-In-Time (JIT) inventory process.

- Shipping and freight forwarding expertise

- Integrated JIT delivery systems

- Kanban style scheduling

- Flexibility with both terms and international payment options

- Extensive warehousing capabilities on multiple continents

Please contact us with any project requirements where our expertise can assist you by calling +1(516)656-3377 or mail us sales@directmed.local.